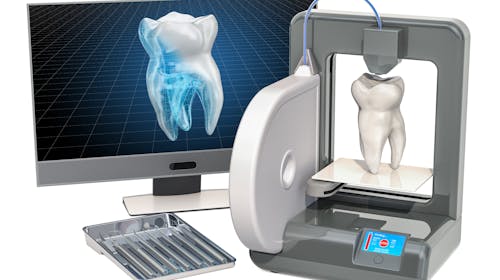

Here we will discuss the standards set for 3d lab dental printer and how these standards help in dealing with dentistry issues.

Accuracy

Printing accuracy is one of the key points to consider when choosing a Dental 3D printer. If you are going to print not only teaching models just to show your patients the treatment process in detail, but working dental products, then you should look for a high-resolution device, as a slight discrepancy can lead to a completely unsatisfactory result.

Speed

Speed is always very important when it comes to business. The high print speed is useful, whether we are talking about dental laboratories or chairside printing in dental clinics, where fast printing helps to minimize the number of patient visits to the dentist.

Support For Biocompatible Materials

It is by far the main feature that a printer should have in order to be called dental. All dental products that come into contact with the patient’s mouth or skin should be certified as biocompatible in your area, so it is highly recommended to check the material compatibility list when choosing a dental 3D printer.

Materials For Dental Printing

Currently, the most popular technology for dental 3D printing is cotton photopolymerization, which includes SLA, DLP, and LCD-based processes, all using liquid resins that are cured by a light source. The selection of special dental resins on the market is therefore really wide. All dental resins are biocompatible and can be used to print temporary or permanent dental parts with the desired properties.

Metal 3D printers are becoming more and more widespread in dentistry because they work with various metal and metal alloy powders, such as titanium or cobalt-chromium, which are traditionally used for the production of crowns, dentures and stents. DMLS printers are able to produce durable, extremely accurate models in a short time. Another popular technology for dental 3D printing is material jetting, which prints with liquid materials plastics or polymers that are cured by UV light. This technology boasts exceptional accuracy of printed models, but printers using this technology are usually bulky and expensive.

As for FDM printing, despite its popularity in many other industries, it has not been widely used in dentistry because FDM machines tend to exhibit lower accuracy than the other technologies mentioned above. However, new models of FDM 3D printers show much higher resolution, accuracy and dimensional stability compared to their predecessors, and now the dental industry can take advantage of all the advantages of FDM technology.

Dental Software For 3d Printing

Almost all dental 3D printing solutions include proprietary software specifically designed for dental offices and laboratories. It usually guides the user through all the stages, starting with uploading a 3D scan to a CAD file and then creating a custom 3D digital model of the dental product. Slicer converts the CAD model into a printable file, usually STL, and prepares the model for printing. After the job is complete, the software sends the print job to the printer. Using specialized software recommended by the manufacturer provides maximum compatibility and ensures the best results without any downtime.